Tape laying process

Higher quality in shorter cycle times – tape laying technology

In many industries, continuous fiber-reinforced thermoplastics are the future of structural composite components. They offer excellent material properties in terms of deflection behavior, rigidity and impact strength. This makes them perfect for the production of large components, which are made stiffer and tougher by local reinforcements in a more cost-effective way. With Dieffenbacher’s Tape Laying Technology for near-net-shape tape layers, you can now produce thermoplastic tapes more quickly and easily, even in mass production.

Dieffenbacher tape laying process

More efficient mass production of thermoplastic components – the Tailored Blank Line

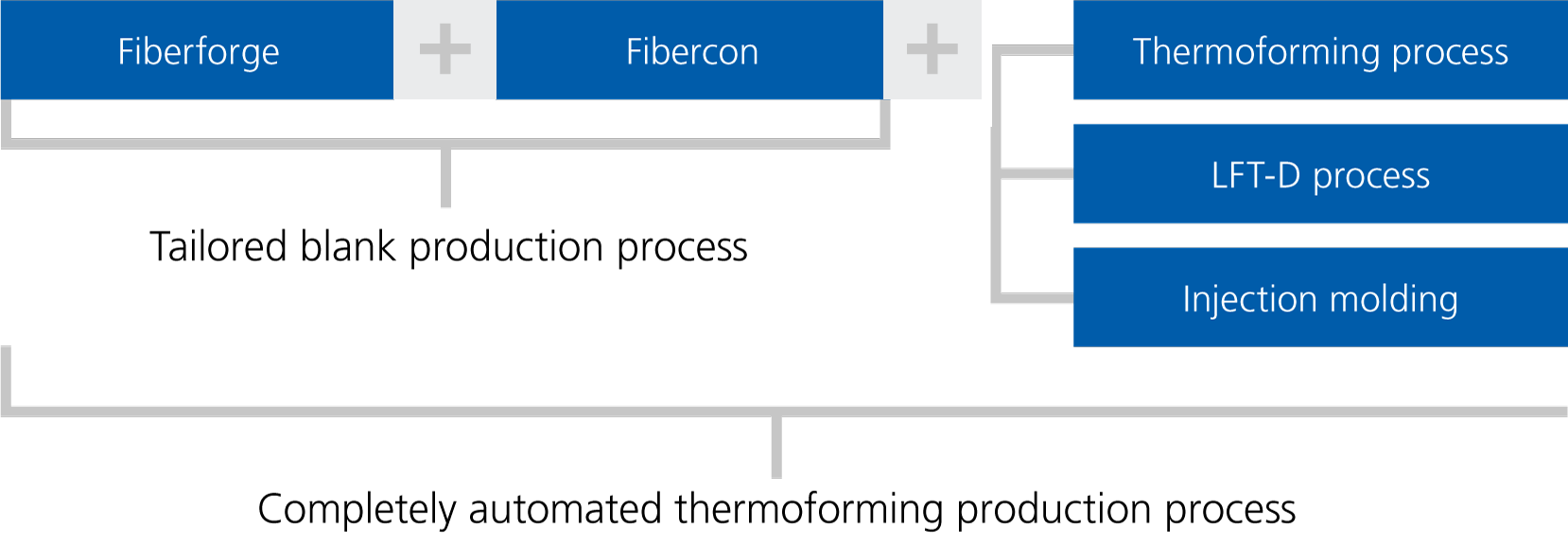

The Tailored Blank Line is a completely integrated production system. It enables you to produce more than one million lightweight components per year using thermoplastic tapes. The Fiberforge tape laying system and the Fibercon consolidation system are at the heart of this solution. Together with upstream and downstream processes such as tape loading and the Dieffenbacher Fiberpress,

you benefit from a flexible and extremely fast production process for thermoplastic components. The Tailored Blank Line can also be combined with other technologies for even more efficient production. Let us advise you on how to further optimize your processes.

Customer benefits

Tailored Blank Line as an integrated production system